Extraction Systems for Woodworking

Top-Tier Dust Collection for Woodworking

With state-of-the-art dust collection technology, we offer reliable solutions for the removal of harmful substances and, thanks to innovative filtration technology, enable the recirculation of cleaned air back into the workspace. This reduces operating costs, increases efficiency, and ensures a healthy working climate. Trust in “Made in Germany” quality and decades of experience in wood dust collection.

Create added value

Operational Safety

AL-KO dust collection systems meet all current requirements and standards for the extraction of wood dust and chips.

Research & Development

With a strong focus on customer needs, AL-KO continuously optimizes its equipment and systems.

Environmental Protection

AL-KO devices and components meet the highest standards of energy efficiency, contributing to the protection of our environment.

Wood Dust Collection Systems – Our Product Overview

Contact Us!

References

FAQs

What Are the Options for Wood Chip Extraction?

There are various systems for wood chip extraction, each suited to different applications:

- Mobile Dust Extractors: Flexible and compact systems, ideal for smaller workshops or as a complement to stationary systems.

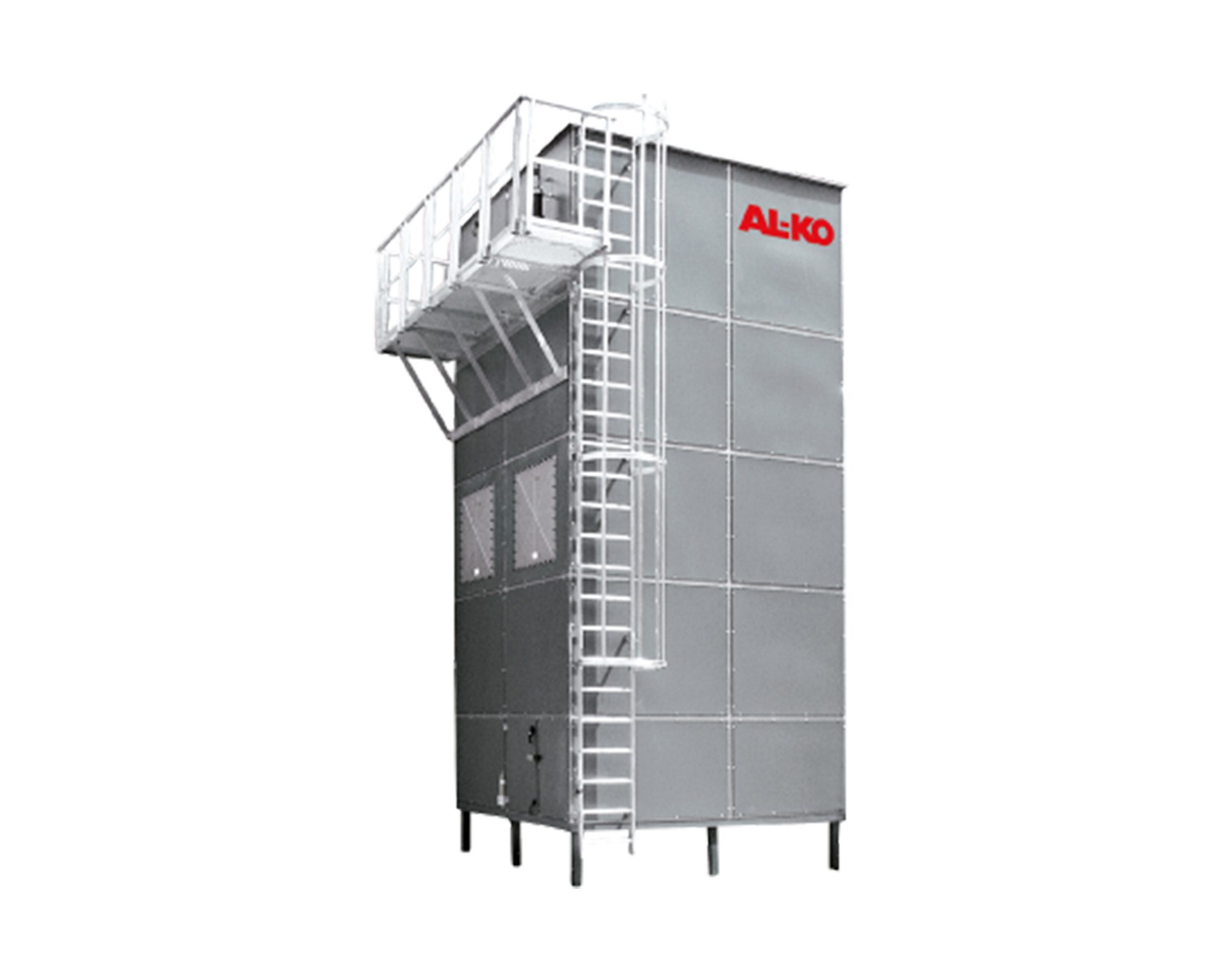

- Stationary Filtration Systems: High-performance dust collection systems like the AL-KO ECO JET and AL-KO PROFI JET® models are suitable for high volume flows. They are ideal for continuous operation.

- Grinding Tables: Specially designed workstations with integrated dust extraction technology for efficient dust removal during grinding tasks.

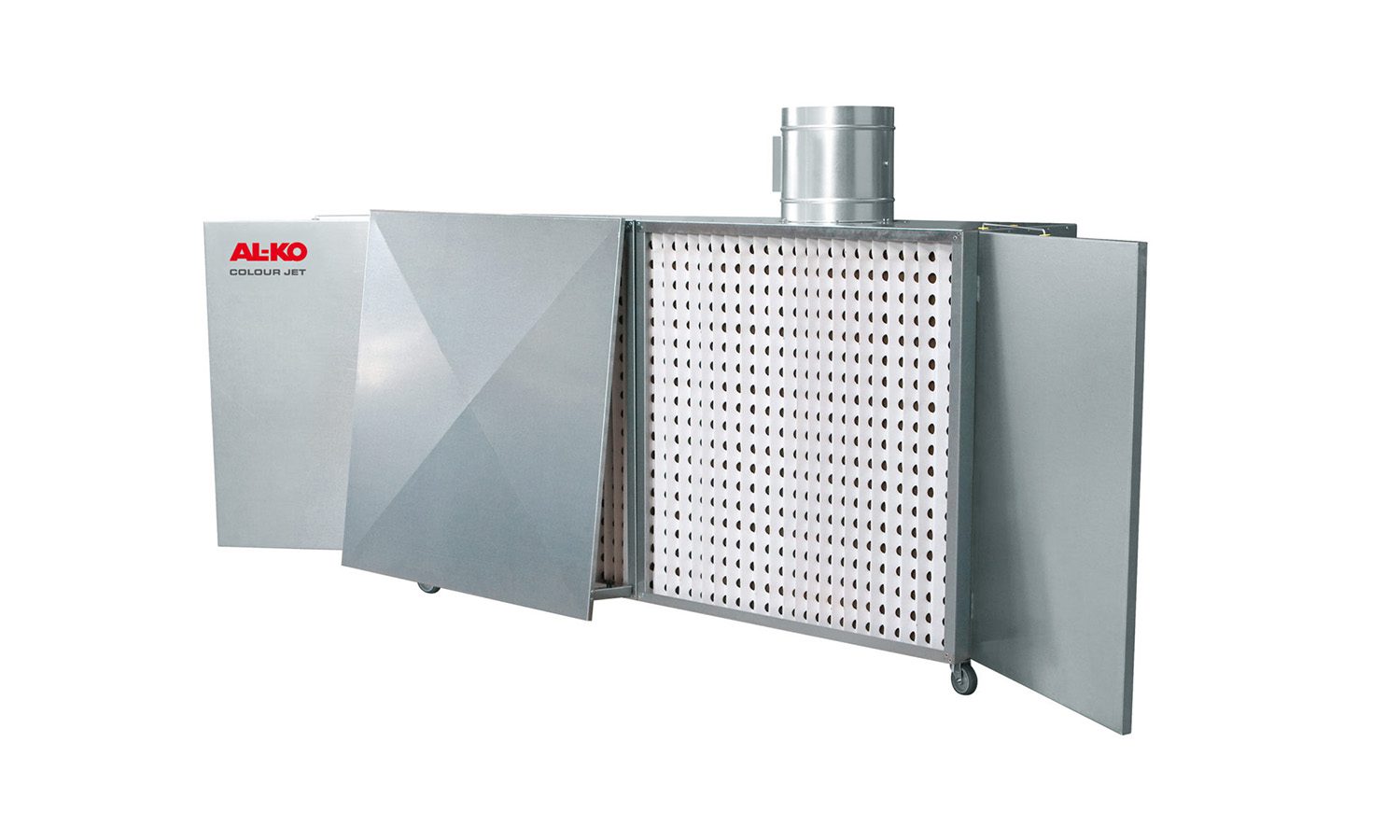

- Paint Mist Extraction: Systems like the AL-KO COLOUR JET, specifically developed for painting tasks in woodworking businesses, efficiently extract paint particles, pigments, and solvents.

Why Is Wood Chip Extraction So Important?

Wood chip extraction is crucial for a safe and healthy work environment. Wood chips and dust can not only contaminate machinery and disrupt production processes but also pose health risks to employees. Fine dust can lead to respiratory diseases and, at high concentrations, can even be explosive. Additionally, effective dust extraction improves product quality and ensures compliance with legal occupational safety regulations.

How Often Should Filtration Systems in Wood Dust Collection Be Maintained?

Filtration systems in wood dust collection should be regularly maintained to ensure optimal performance. The maintenance interval depends on the intensity of use and the type of particles being filtered. For continuous operation, it is recommended to inspect the filters at least once a year and replace them if necessary. Visible contamination or a decrease in extraction performance are signs that a filter change is needed.

What Is Meant by Extraction Technology for Woodworking?

Dust collection technology for woodworking encompasses all systems, devices, and methods used to capture and filter wood chips, dust, and paint mist. This includes mobile dust collectors, stationary filtration systems, grinding tables, and specialized paint mist extraction systems. AL-KO’s dust collection technology ensures that harmful particles are efficiently removed, providing clean air in the workspace. Modern systems also enable the recirculation of clean air, leading to additional energy savings.

Which Dust Collection System Is Best Suited for Small Workshops?

For small workshops, mobile dust collectors or compact filtration systems are particularly suitable. Systems like the AL-KO POWER UNIT® offer maximum volume flows ranging from 790 to 10,000 m³/h, making them ideal for small to medium dust collection needs. Mobile dust collectors are flexible, space-saving, and can be easily used at various workstations. They also enable efficient extraction of wood chips and dust directly at the source.

Which Dust Collection System Is Best Suited for Industrial Woodworking?

For industrial woodworking, stationary filtration systems like the AL-KO ECO JET and AL-KO PROFI JET® models are ideal. These high-performance systems are specifically designed for large volume flows and continuous operation. With excellent sound insulation and heat recovery, they offer the highest energy efficiency. The PROFI JET® systems also feature outstanding thermal insulation with insulated panels, which is particularly advantageous for recirculating clean air. Their modular design allows the system to be flexibly and modularly expanded to meet growing production needs.