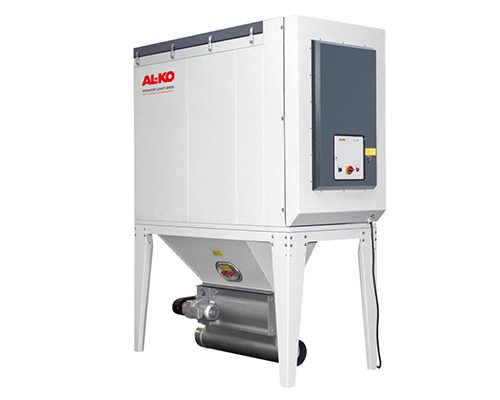

Pure Air Dust Extractors AL-KO POWER UNIT®

The dust extractors in the AL-KO POWER UNIT series are used in trade and industry. They can be connected to individual machines, machining centres or to multiple extraction points via piping. The mobile clean air dust extractors have a high extraction capacity and a small footprint. They are available in eight different sizes with motor power from 1.1 to 15 kW and an air flow rates up to 10,000 m³/h.

AL-KO quality

Receive consultation in person

Operating principle

With the AL-KO POWER UNIT clean air dust extractor, the powerful fan on the clean air side draws the dust-laden air into the extraction unit. The integrated pre-separator guides chips and coarse particles directly into the collection container. The remaining fine dust is separated by the class "M" dust filters. The AL-KO OPTI JET® filter cleaning system uses compressed air jets to remove adhering dust from the filters during the extraction process, thus ensuring constant extraction performance. A large-volume mobile collection container is included as standard.

Your benefits

- Consistently high suction power due to integrated pre-separator and AL-KO OPTI JET filter cleaning system

- Reduced heating costs, since 100 % recirculating air operation is possible in many cases

- Compact design for smaller footprint

- Low-dust emptying due to patented integrated dust compartment on the collecting container

- Broad power spectrum

- Extremely quiet due to highly effective sound insulation

- Extensive accessories and numerous options for individual device configurations

- BAFA eligible under Module 1

Applications

- Dust extraction at production machinery, machining centers, pipeline systems with multiple extraction points

- Direct extraction in continuous operation

- Applications for high-power mobile units

- In industries such as timber processing and woodworking, carpentry, joinery, furniture making, plastics manufacturing and processing, paper production, orthopedics and many others

Options & variants

- Rotary lock valve, briquette press or round discharge instead of collecting container

- Patented AL-KO LEVEL CONTROL 21 fill level monitor

- Different filter materials for the particular application

- Integrated compressor for filter cleaning

- Additional sound absorbers and exhaust air hood

- Control options also with frequency inverter

- Extensive accessories, such as pipes, hoses, capturing hoods, etc.

Technical data

AL-KO POWER UNIT

| Device type | Power Unit 100 | Power Unit 120 | Power Unit 140 | Power Unit 160 | Power Unit 200 | Power Unit 250 | Power Unit 300 | Power Unit 350 | Power Unit 350+ |

|---|---|---|---|---|---|---|---|---|---|

| Suction nozzle Ø in mm | 100 | 120 | 140 | 160 | 200 | 250 | 300 | 350 | 355 |

| Max. airflow in m3/h | 790 | 1,140 | 1,600 | 2,000 | 3,010 | 4,900 | 6,000 | 8,500 | 10,000 |

| Max. vacuum in Pa. | 2,600 | 2,900 | 2,700 | 2,800 | 2,900 | 3,500 | 3,900 | 3,800 | 4,200 |

| Motor rating in kW | 1.1 | 1.5 | 2.2 | 2.2 | 3 | 7.5 | 7.5 | 11 | 15 |

| Filter area m2 | 4.1 | 5.1 | 6.3 | 9.1 | 13.8 | 22.4 | 30 | 73 | 73 |

| Sound pressure level dB(A) | 69 | 71 | 70 | 70 | 72 | 71 | 71 | 71 | 73 |

| Dimensions (L x W x H) in mm | 1,178 x 650 x 1,973 | 1,178 x 650 x 1,973 | 1,1801 x 830 x 2,050 | 1,800 x 830 x 2,050 | 2,296 x 830 x 2,050 | 2,351 x 1,058 x 2,361 | 3,000 x 1,058 x 2,361 | 3,129 x 1,058 x 2,361 | 3,130 x 1,058 x 2,361 |

All values are approximate and refer to the basic version; subject to technical modifications