AL-KO FLEX UNIT ECO central filter system

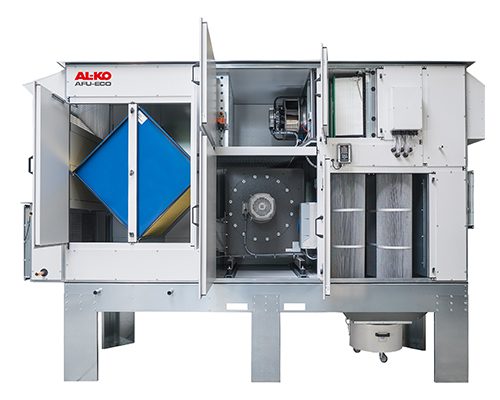

The systems of the FLEX UNIT ECO series offer a unique combination of extraction technology and heat recovery in a compact design. They are available in two standard versions: for extraction of dusts and welding fumes.

AL-KO quality

Receive consultation in person

Operating principle

AL-KO FLEX UNIT ECO systems combine extraction and filtration technology in the first stage with the downstream ventilation technology in a compact unit. They are available in versions for dusts (FLEX UNIT D ECO) and welding fumes (FLEX UNIT F ECO). Time-proven AL-KO filtration technology separates the extracted dust or welding fumes by means of efficient filter cartridges. The filtered air then passes through a downstream heat exchanger and is released into the environment. The heat exchanger takes about 73 percent of the heat from the exhaust air and mixes it with fresh air drawn in by a fresh air fan before returning it to the workspace.

Your benefits

- Extraction system and heat recovery in one compact system

- Optimal combination of extraction and ventilation technology

- Maximum energy efficiency

- Plug-and-play system technology, complete with control unit

- Four high-performance standard versions

- Customized solutions

- Eligible through government funding programs

- Best air quality with maximum energy efficiency

- IE3 motors in combination with frequency converters for low power consumption

Applications

- For hazardous dusts and fumes that are subject to regulations for exhaust air conduction and fresh air supply, for example in the machining and welding of stainless steel

- Extraction in grinding, welding, polishing and other processes

- Direct extraction at machines, welding stations, booths and enclosures

Options & variants

- Also available with additional heating or cooling module

- Diverse filter media

- Required pipe system, capturing hoods, extraction arms and much more

- Maintenance and service contracts

- IE 4 motors or higher value on request

- HEPA post-filter class H13 or H14 for highest filter performance

Technical data

AL-KO FLEX UNIT D ECO

| Device type | FLEX UNIT D 78-7.5 ECO |

FLEX UNIT D 117-11 ECO |

FLEX UNIT D 156-15 ECO |

FLEX UNIT D 234-22 ECO |

|---|---|---|---|---|

| Airflow in m³/h | 5,200 | 9,000 | 10,400 | 18,000 |

| Vacuum in Pa. | 2,800 | 2,800 | 2,800 | 2,800 |

| Nominal motor power in kW Extraction unit | 7.5 | 11 | 2 x 7.5 | 2 x 11 |

| Nominal motor power in kW Supply air WRG | 4.5 | 4.5 | 2 x 4.5 | 2 x 4.5 |

| Filter area in m² | 78 | 117 | 156 | 234 |

| Sound pressure level dB(A) | 65 | 67 | 65 | 66 |

| Dimensions W x D x H in mm | 4,088 x 1,414 x 3,103 | 4,850 x 1,414 x 3,103 | 4,088 x 2,714 x 3,103 | 4,850 x 2,714 x 3,103 |

AL-KO FLEX UNIT F ECO

| Device type | FLEX UNIT F 126-7.5 ECO |

FLEX UNIT F 189-11 ECO |

FLEX UNIT F 252-15 ECO |

FLEX UNIT F 378-22 ECO |

|---|---|---|---|---|

| Airflow in m³/h | 5,200 | 9,000 | 10,400 | 18,000 |

| Vacuum in Pa. | 2,800 | 2,800 | 2,800 | 2,800 |

| Nominal motor power in kW Extraction unit | 7.5 | 11 | 2 x 7.5 | 2 x 11 |

| Nominal motor power in kW Supply air WRG | 4.5 | 4.5 | 2 x 4.5 | 2 x 4.5 |

| Filter area in m² | 126 | 189 | 252 | 378 |

| Sound pressure level dB(A) | 65 | 67 | 65 | 66 |

| Dimensions W x D x H in mm | 4,088 x 1,414 x 3,103 | 4,850 x 1,414 x 3,103 | 4,088 x 2,714 x 3,103 | 4,850 x 2,714 x 3,103 |

All values are approximate and refer to the basic version; subject to technical modifications.