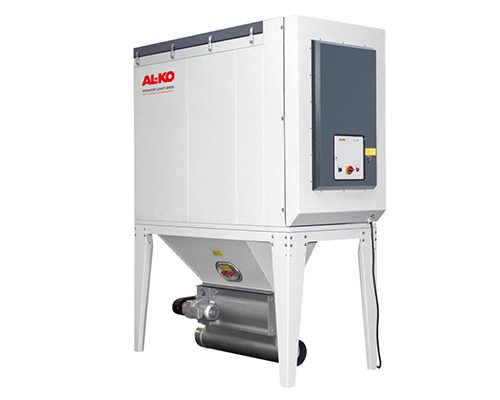

Efficient extraction with rotary valves by AL-KO

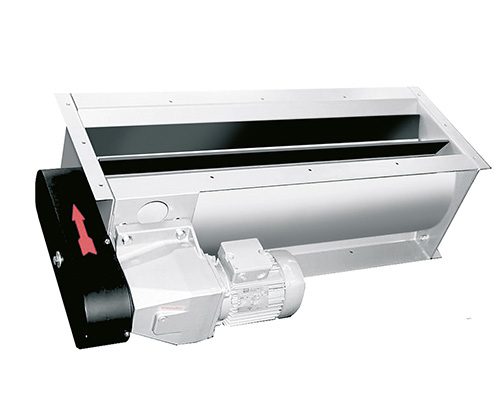

Rotary valves are used to dispose of the extracted material. Using a rotor, the rotary valve discharges material continuously and without pressure. This allows the extraction system to continue working without interruption. Rotary valves transport chips and other particles into containers or big bags provided by the customer. The rotary valves can be combined with all dust extractors and extraction systems from AL-KO Extraction Technology. All are ATEX certified.

AL-KO quality

Receive consultation in person

Operating principle

Rotary lock valves are used optionally instead of collecting containers on AL-KO dust extractors and extraction systems. Rotary lock valves transport the separated material continuously and without pressure into a container, big bag, etc. provided by the customer. Since this happens continuously, there is no interruption in the extraction.

Your benefits

- Uninterrupted operation of the extraction system, since no collecting containers have to be emptied

- No loose material in the extraction system, therefore reducing the risk of fire and explosion

- Collection of separated material in containers of your choice

- Tested in accordance with ATEX product directive 2014/34/EU

Applications

- For large quantities of materials that require continuous extraction

- For dry and free-flowing materials (wood, plastic, metal, etc.)

Options & variants

- Version with blow-off attachment for transport of the discharged material

- Mounting option on round discharge

- Application-specific custom version is possible

Technical data

Efficient extraction with rotary valves

| Device type | 440/1 | 440 | 960/1 | 960 |

|---|---|---|---|---|

| Motor rating in kW | 0.18 | 0.37 | 0.18 | 0.37 |

| Max. capacity in l/h | 7,250 | 21,750 | 15,816 | 47,450 |

| Speed in rpm | 4 | 11 | 4 | 11 |

| Weight kg | 70 | 70 | 106 | 106 |

All values are approximate and refer to the basic version; subject to technical modifications